Unit 3 Assignment 1: Handcut Plywood and Assignment 2: Lasercut Cardboard

This unit was a step into a new level of unknown. I have never done any digital design or 3D design. I noticed that I kind of lost my way for the first few weeks, given that with Units 1 and 2, my hands led the way and were integral to the decision-making and testing of materials and ideas. For unit 3, we started on a computer screen, without the advantage of hands-on material testing to help figure out what could/would work. I think it is likely that I would have made different choices with a manual starting place. However, there was a real intellectual pleasure in figuring out the basics of three or four new computer programs, getting glimpses of how powerful the tools are for 3D practice.

From the research assignment Unit 3, I knew I was interested in large geometric shapes and in curvilinear shapes with spacers. At my first encounter with MeshMixer I found an icosahedron (20-sided regular polyhedron), a shape I have made in many variations over the years of doing modular origami. I think I latched on to this familiar touchstone since everything else was novel. I made two variants for the different media:

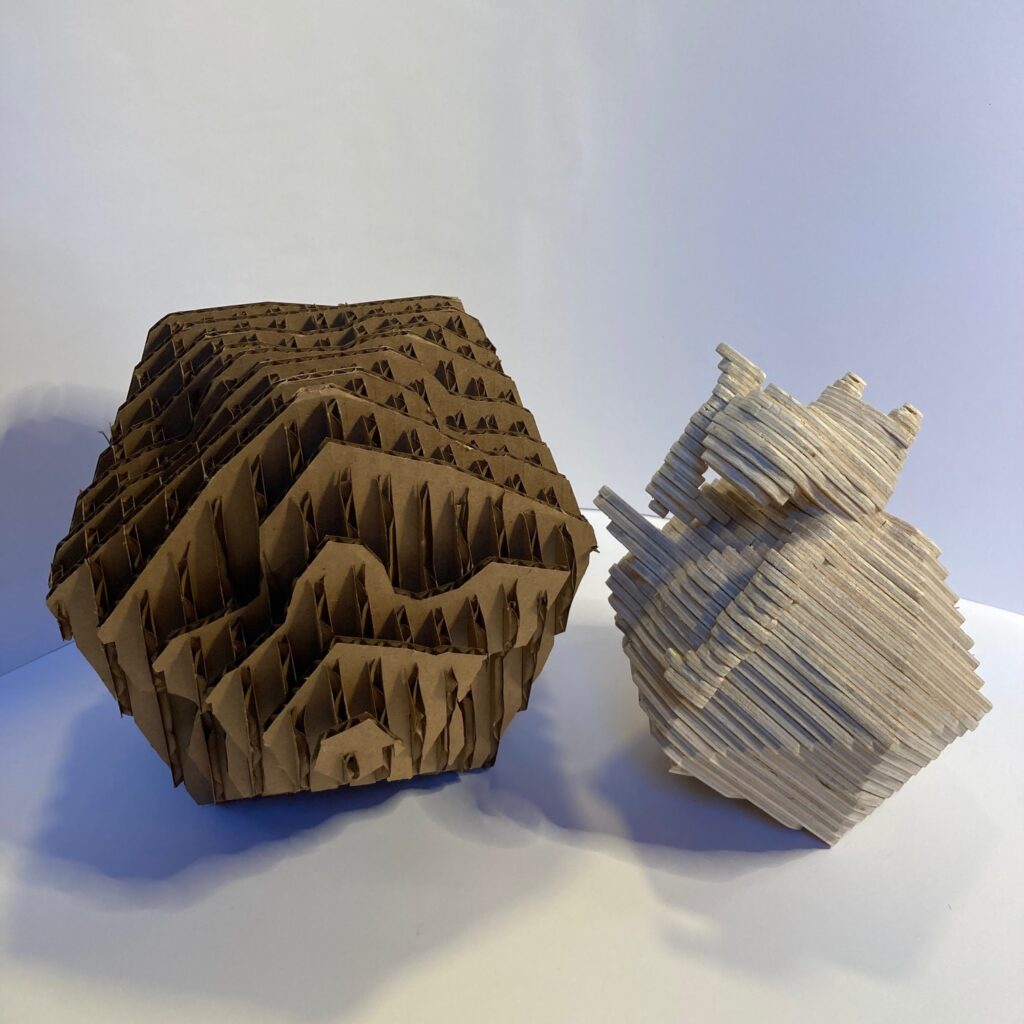

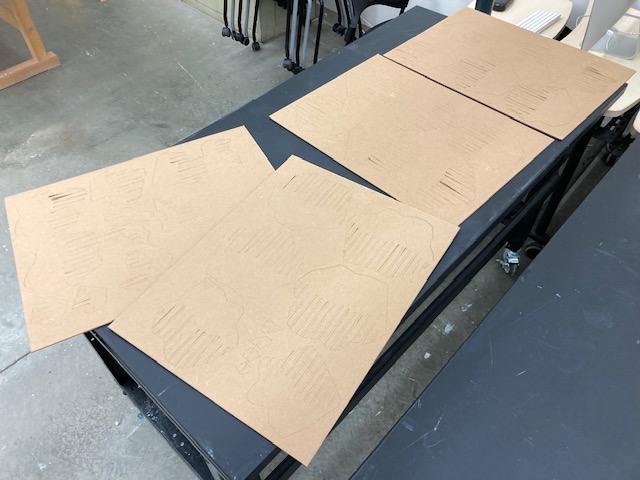

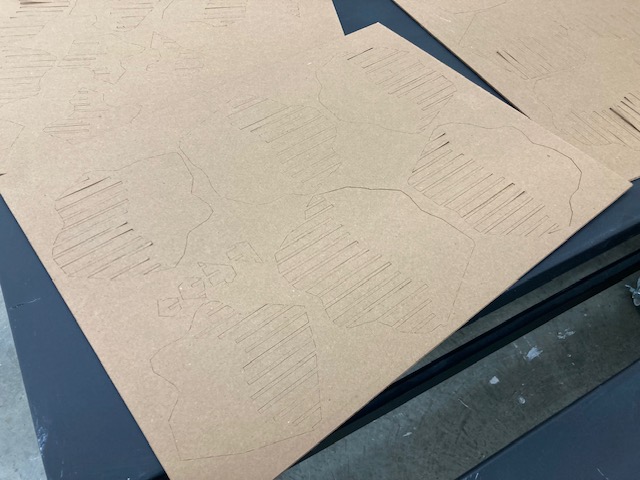

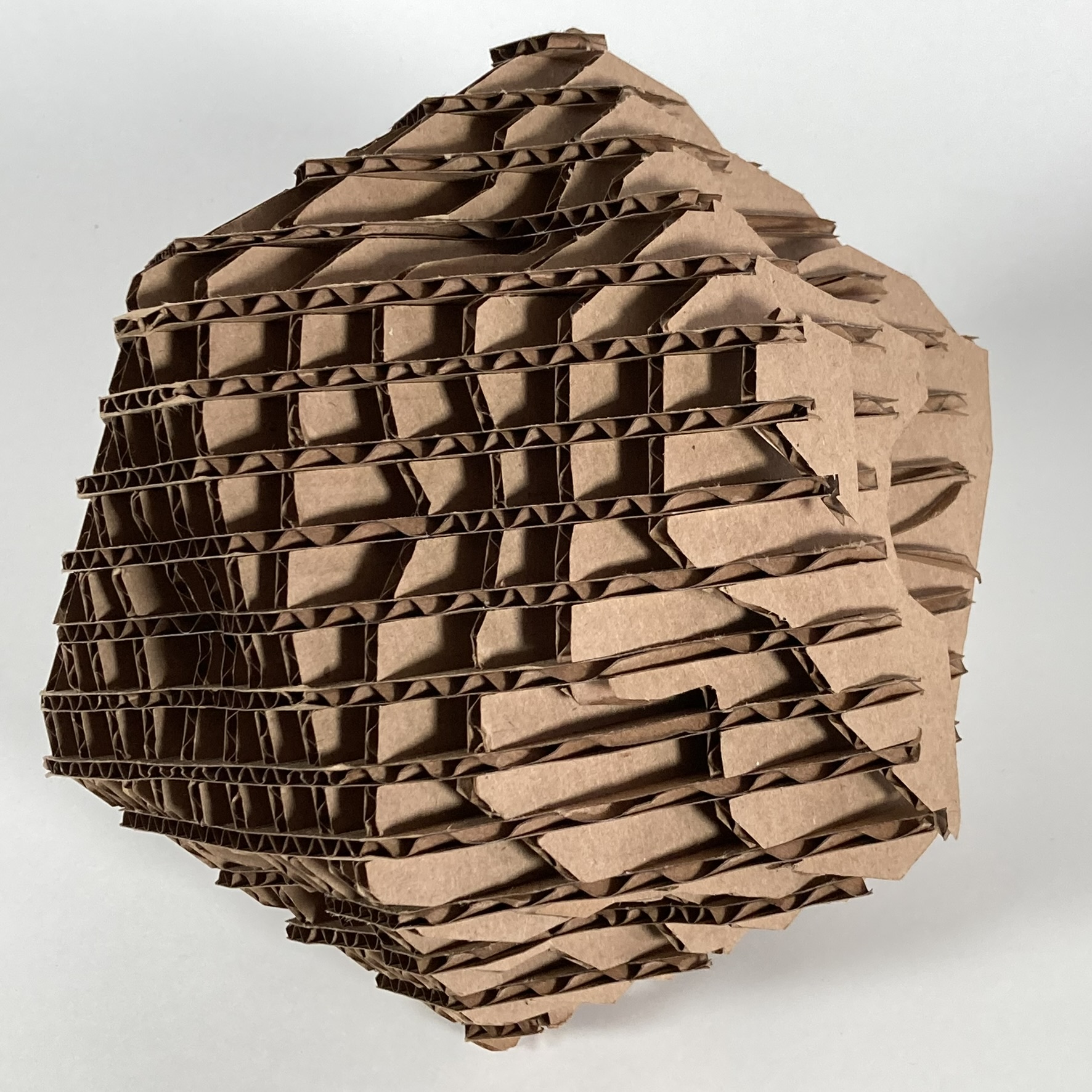

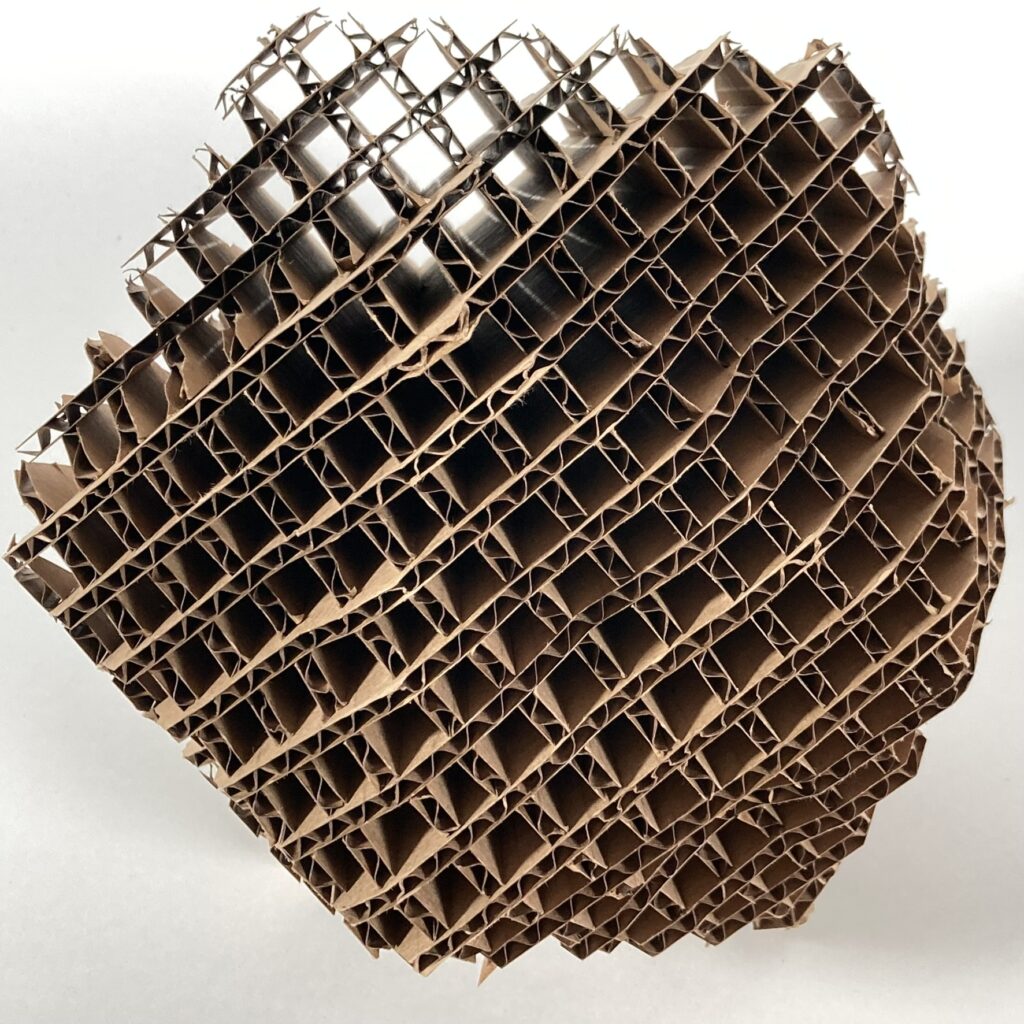

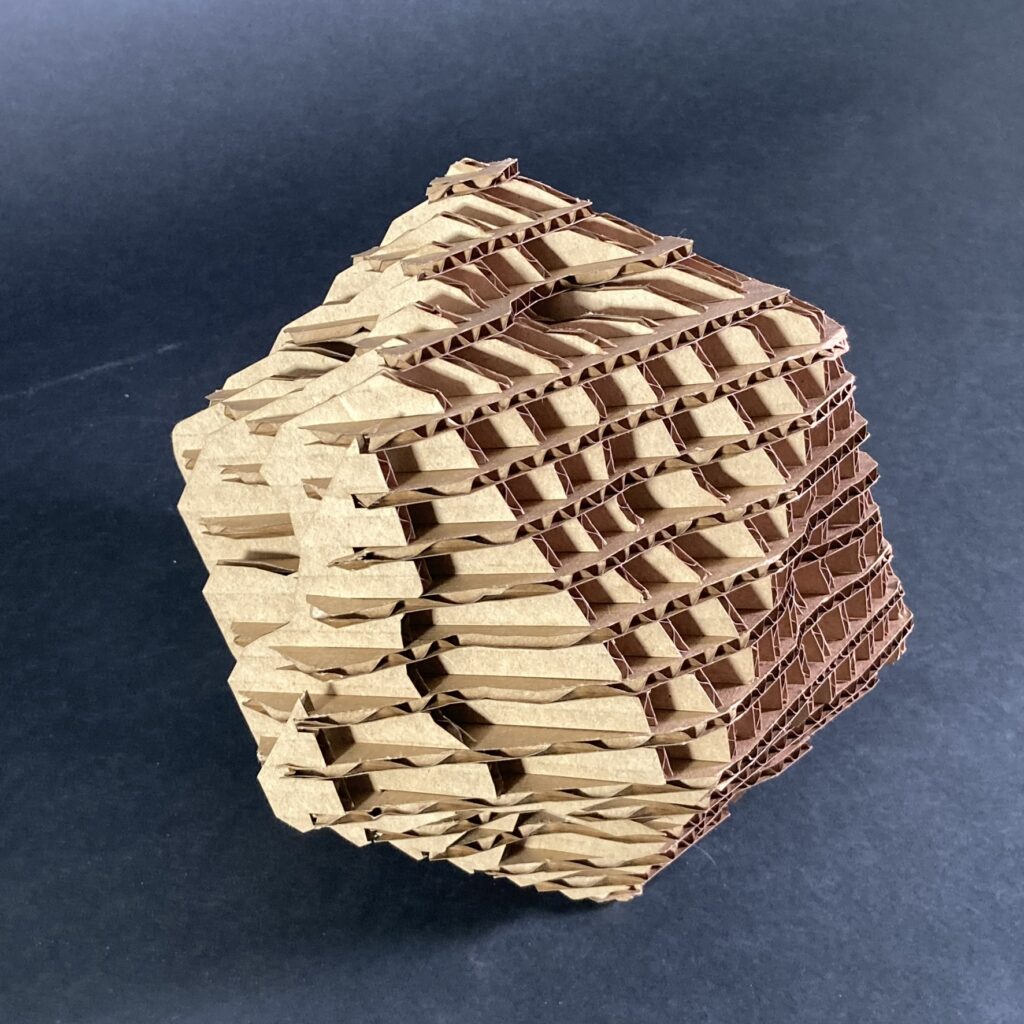

LASERCUT CARDBOARD: This version has an inward dimple on each of the twenty faces. I experimented with many directions of slicing to get the largest possible number of pieces in an intersecting pattern within the limits of 4 sheets of cardboard, hoping to convey the subtleties of these dimples. Not sure it will hold in the end as many of the small end bits of cardboard may be lost or too fragile to use.

November 28th: Lasercut Cardboard arrived! It smells like burnt paper — not surprising, I guess. See below, the cut sheets still intact — ended up removing the pieces one at a time while following along the assembly process on Slicer, because all my pieces looked kinda similar and they are not labeled with part numbers on the cardboard (I could work out which was which by looking at the diagrams in Slicer).

A couple of the finest edge cuts were lost due to being too small. One not-so-small piece was completely separated from its mother piece but I was able to salvage and glue in place. Also glued the two outermost smallest pieces for more stability. All the rest held really well with snug fit. It took some concentration, therefore completely forgot to take photos along the way. Took about 4 hours in the end…

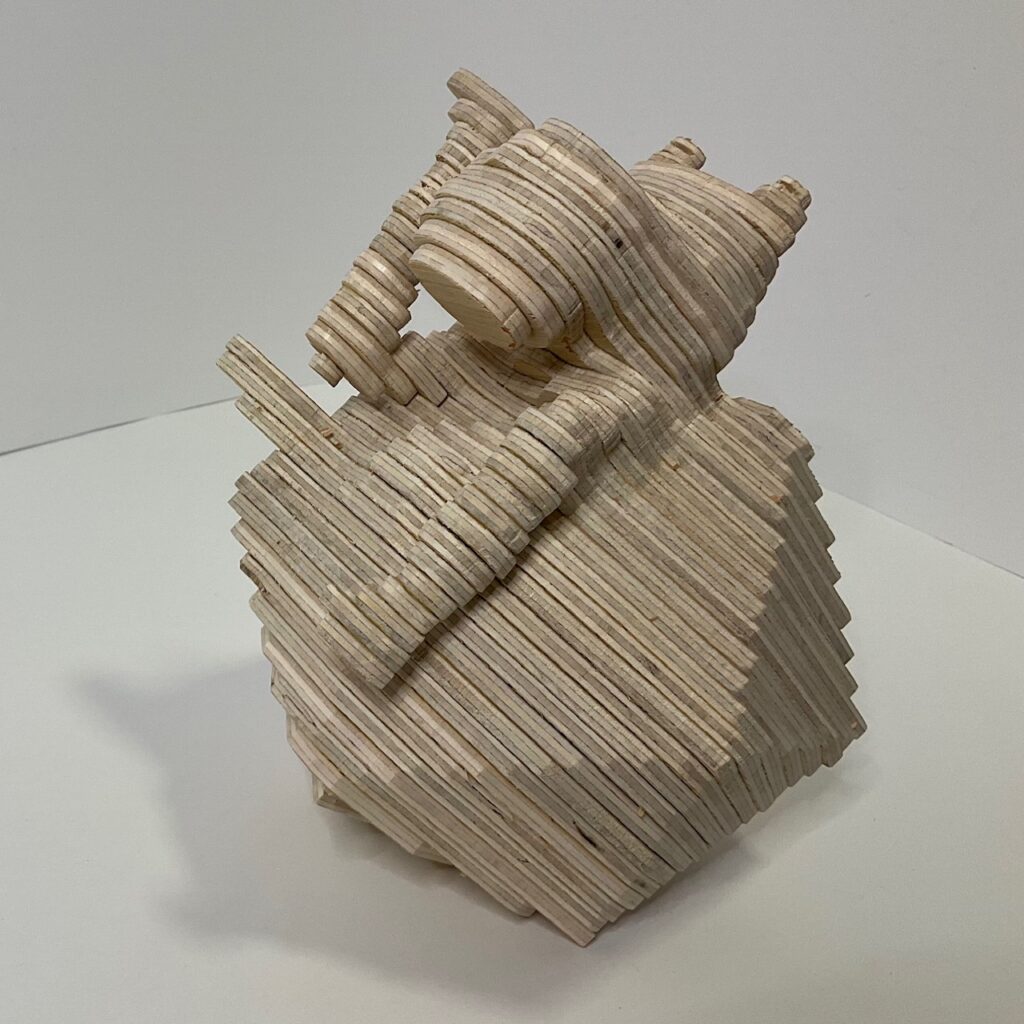

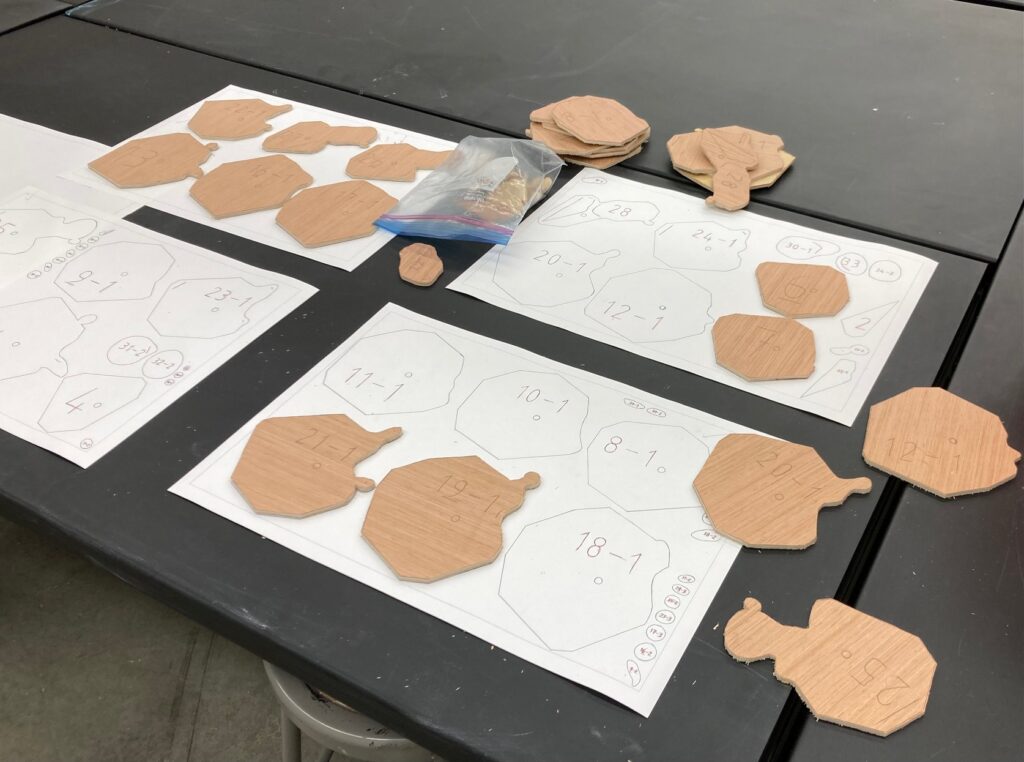

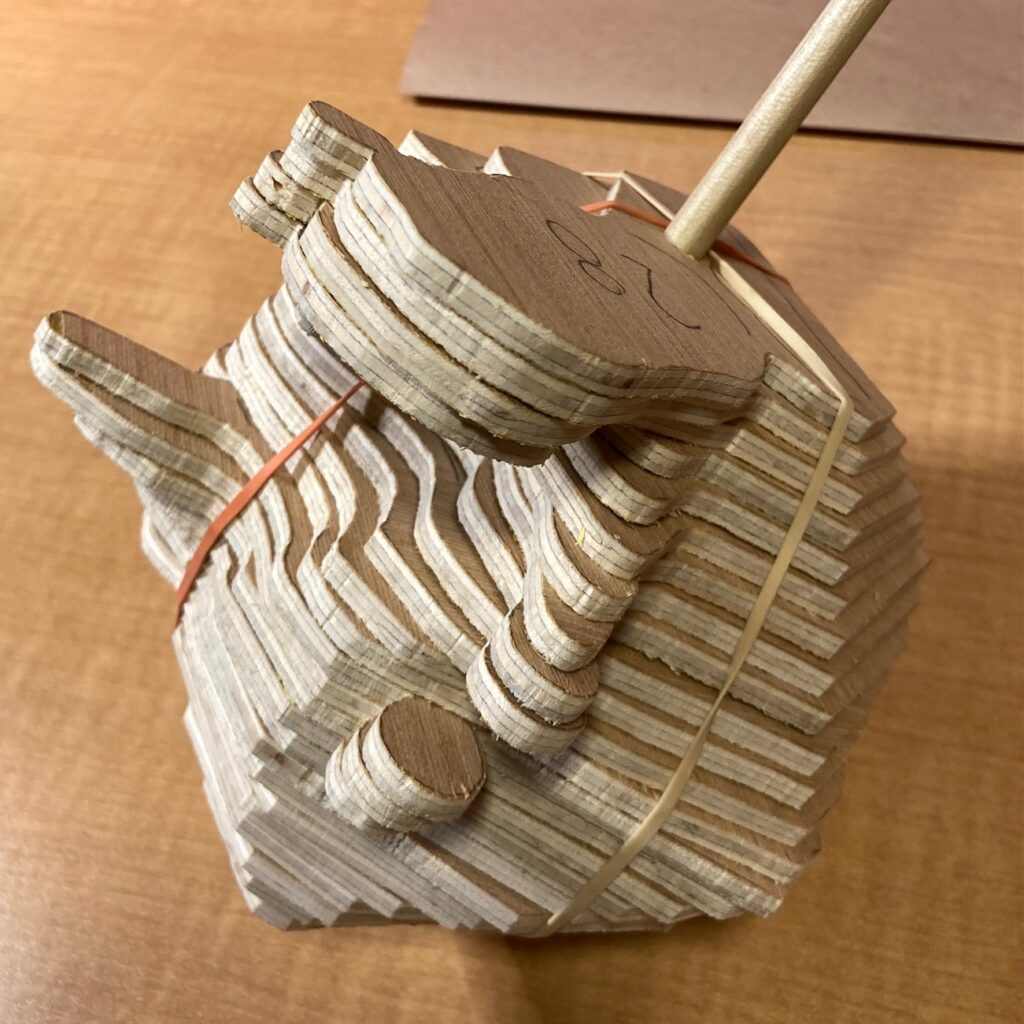

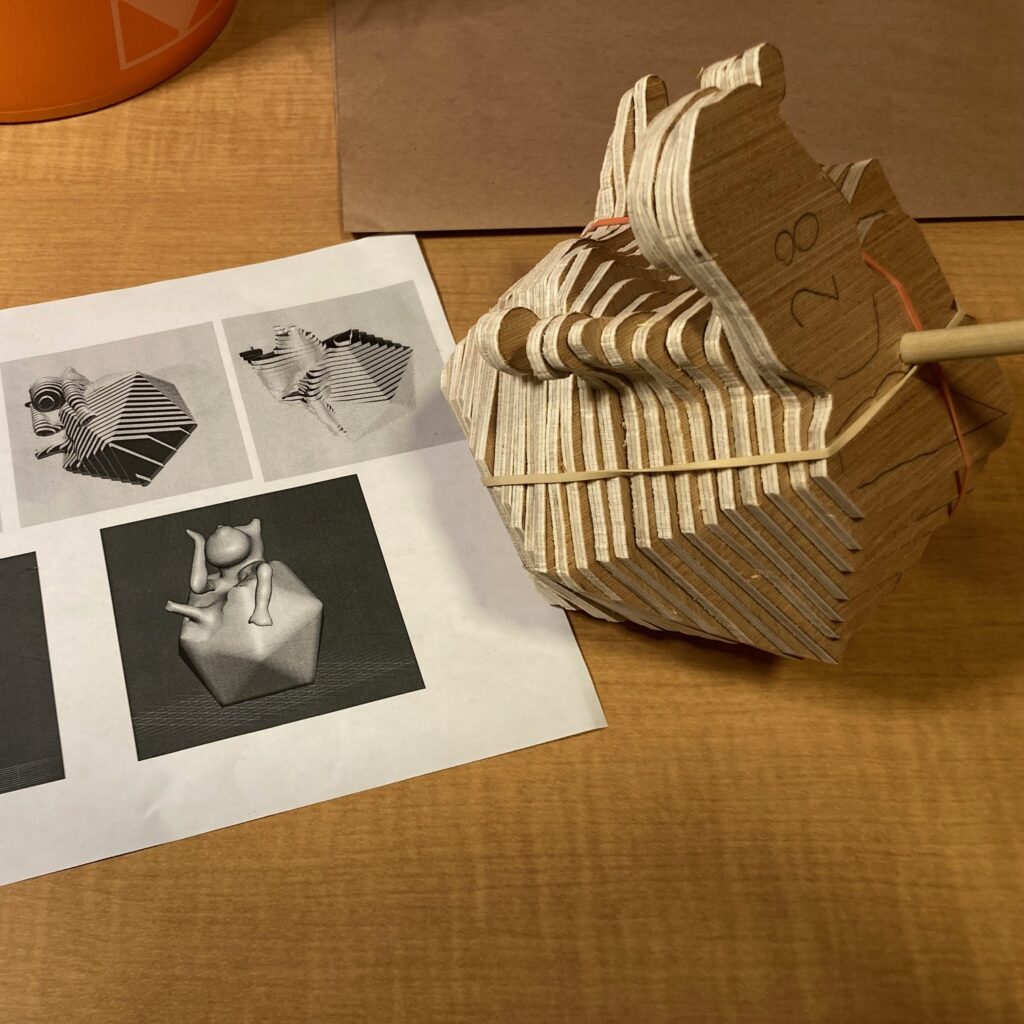

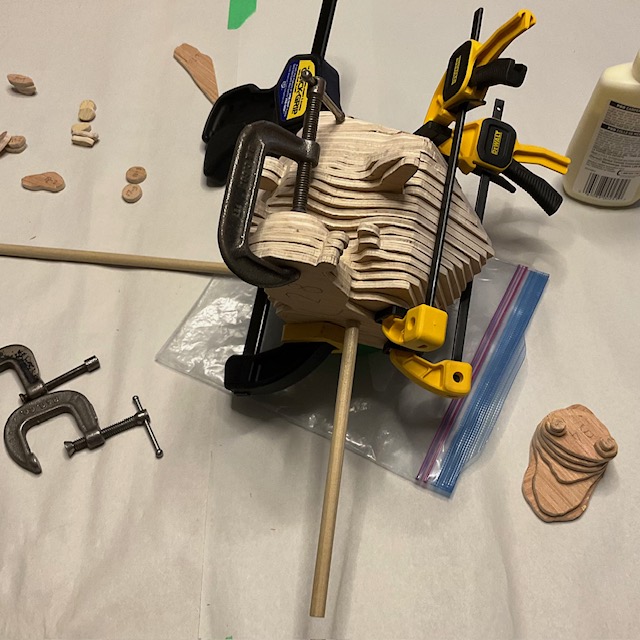

HANDCUT WOOD: For this version I “cracked open” the icosahedron and shaped a strange hybrid creature (vaguely dog-like) emerging from within. I chose a slicing angle to give me the best version of the limbs and head emerging from within, but does a disservice to the smoothness of the icosahedron sides, and also features more of the unfinished / less finished side of the plywood in the process, which I hadn’t anticipated. Waiting to see how my glueing and sanding can address, enhance, or play with these surprises…

Here are a few shots of plywood work in progress:

and the final icosa-creature: